Sherman mattress construction.

We make all Sherman mattresses in the traditional method, by building the mattress from the spring unit up, with many parts of the process still completed by hand.

With access to an international supply chain, a comprehensive range of component technologies are used, many of which have been designed to meet our specific quality and performance requirements. We are relentlessly focused on quality – we use only the highest quality fabrics, innerspring units and foams and obsess over every detail.

In the Sherman factory, only the heavy lifting of the mattresses between process areas has been automised. All other tasks, such as applying the foams or stitching the fabric layers to the mattress, are still done by craftsmen’s hands.

The construction process begins when the spring unit is placed on a high table or conveyor belt ready for the upholstery layers to be built around the unit.

In some mattress factories, the entire construction time from here until the mattress is bagged can be as little as 20 minutes. As Sherman mattresses are a more premium style, we take a little longer and place more care into the stitching and application of the foams.

The first layer of upholstery over the spring unit is an insulation layer. Unlike some manufacturers who use a synthetic lining, we natural felt that has been manufactured with recycled cotton. The primary role for this layer is to prevent the foams and fillings from sinking into the spring unit.

The felt will be attached over the spring unit with solid metal rings, known as hog rings. These rings are applied with a high-pressure gun that fastens the ring through the felt and around one of the outer springs.

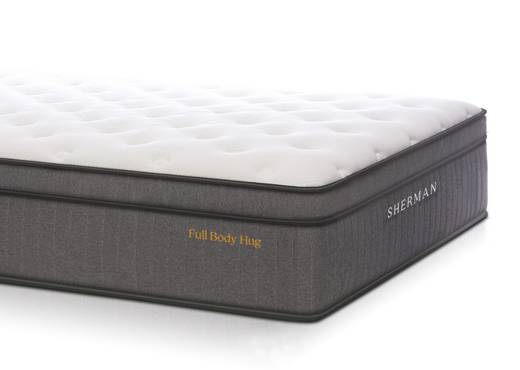

Next will come the base layer of foam, depending on the mattress, this is usually the firmest layer of all the foams used in the comfort layers.

Following this will be the final layers of foams, finishing with the most premium foams such as our memory foam. A well-constructed mattress will always have these premium foams as close to the top of the mattress as possible so that the sleeper will be able to utilise the pressure-relieving properties of these foams.

Foam layers are glued with a glue mixture that bonds the foams without causing them to erode. This glue is often a mix of natural rubbers and synthetics.

Fixing these foam layers together is an essential step in mattress construction, for without this, the layers will undoubtably shift whenever the sleeper turns or moves on the mattress.

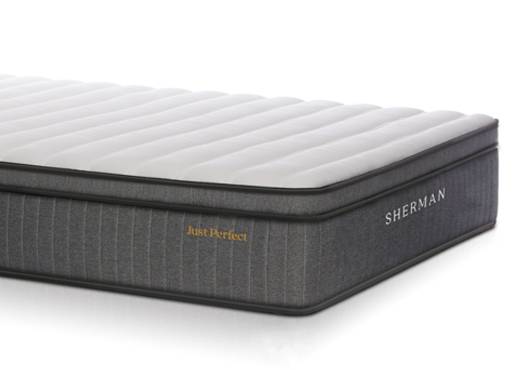

Once all of the comfort layers have been applied over the spring unit, a pre-cut, quilted border is wrapped around the sides of the mattress and sewn into place.

The mattress quilt is then applied. This will be a one piece layer that has been pre-sewn to the exact size of the mattress. This panel consists of the top mattress fabric, a polyester filling and an underside fabric, with all layers sewn together by a huge quilting machine.

The quilt panel, upper foam layers and mattress border fabric will then be sewn together using a wide fabric tape or ribbon.

Even this last process will usually be done by hand, with the worker pushing the entire mattress through a sewing machine known as a tape edging machine. It is quite a skill to be able to achieve a nice straight line as this ribbon stitches together the outer layers of the mattress.

The mattress is then flipped and another layer of insulation felt will be attached to the underside of the spring unit and joined to the springs with hog rings.

Finally, an underside panel of fabric is sewn together with more fabric tape to join the border fabric.

Before being placed into a mattress bag, the finished product is assessed by a quality-control worker who will check the overall construction and stitching and trim any loose threads left over from the quilting and tape edging machines.

We publish our full list of specifications used in all of our mattresses, see those here.

Go back to the article: "What's the best mattress for me?"